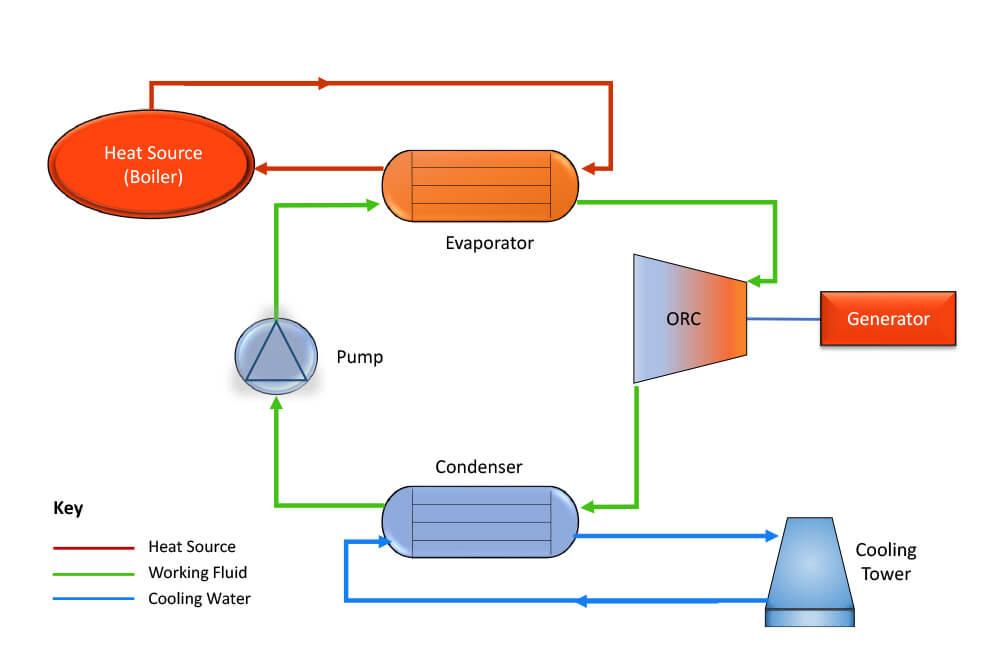

The Power System operates using a thermodynamic principle known as the Organic Rankine Cycle or ORC (see Figure 1.)

Based on a thermodynamic cycle known as the Organic Rankine Cycle (ORC), the Power System converts low to moderate temperature resource fluids into electricity through vaporizing and expanding a working fluid in a closed system.

Figure 1 – Power System Schematic

- Hot fluid/source enters the evaporator to heat Power System working fluid, a refrigerant called R1233zd(e), until it is vaporized.

- High pressure, hot vaporized working fluid then enters the power module and drives a turbine to produce electrical power.

- Low pressure, expanded vapor cycles through a condenser where it is cooled and condensed.

- The cooled liquid is then sent to the pump, boosted in pressure and sent back to the evaporator to repeat the cycle.

- Heat released during condensation is conveyed to the cooling tower.

Video on How ORC System Works:

SYSTEM COMPONENTS

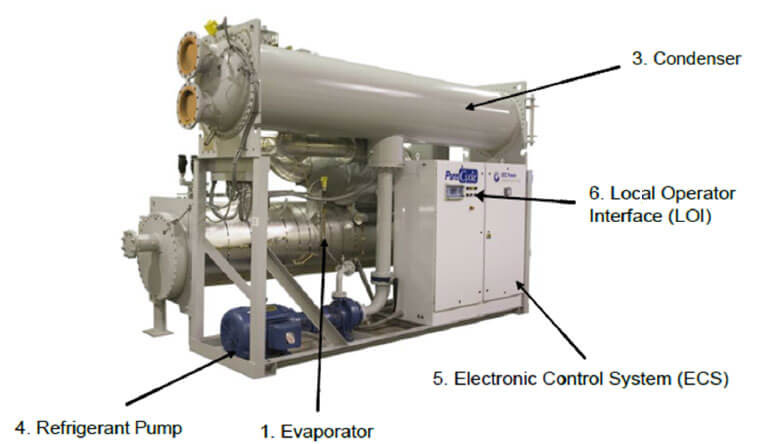

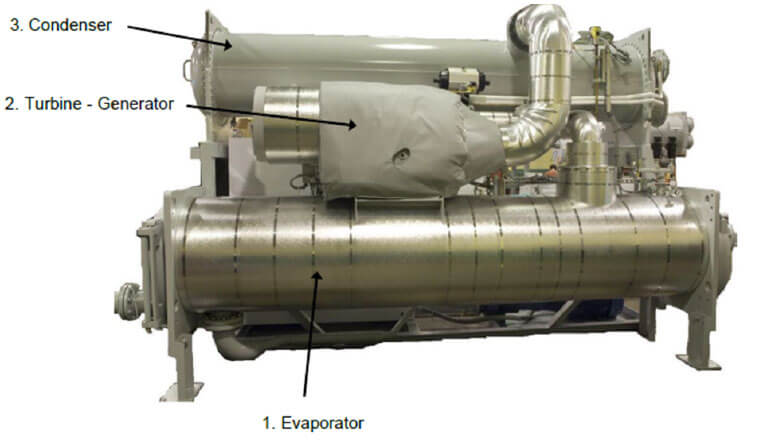

The Power System is supplied complete on skid-mounted modular. The assembled modular which comprise of the turbine generator assembly, condenser, evaporator, electrical control system (ECS) and refrigerant pump. All equipment on skid will be tested after assembly before shipment.

Figure 2 – Power System Schematic (Front View)

Figure 3 – Power System (Rear View)

REMOTE MONITORING SYSTEM (RMS)

The Remote Monitoring System provides local and remote monitoring and control of the power system. Customer can remote to the system by establishing the connection via Internet Web Portal. Users can access current and past power plant operating data. a customer site from the Internet. Product alarms are stored along with product data in the central database. The RMS design leverages TICA’ experience in remote monitoring and provides low-cost installation and operation.

Figure 5 – Remote Monitoring System Architecture

RMS Capabilities/Features

The RMS collects data and forwards it to a database, accessible through WebCTRL® software; a web server interface that supports remote monitoring/control through web browser. Communication to the Remote Monitoring Server is established, via customer’s dedicated broadband connection with a unique static IP address and/or appropriate routing equipment. Bandwidth capability should be T1 or equivalent (min. bandwidth 1.54 Mb) for best functionality.

Data encryption techniques will be use to provide secure communication.

Project Reference Photo